Smart FEZ

SMART FEZ

The Klaipėda Free Economic Zone is a community of modern companies implementing modern technologies and often conducting research as well as product and process design. Advanced solutions not only allow the companies of the Klaipėda FEZ to be competitive in the global markets, but also to contribute to more sustainable activities and convenience for employees.

A survey conducted in 2020 in the Klaipėda region showed that progress, innovation and modernity are some of the main factors that make communities value the Klaipėda FEZ.

We invite you to get acquainted with the solutions of the Klaipėda FEZ management company and companies operating here in the fields of green energy, sustainable mobility, digitisation, research and other areas related to innovations.

KLAIPĖDA FEZ MANAGEMENT COMPANY

Innovation principles of the Klaipėda FEZ management company:

- Klaipėda FEZ gives priority to modern, high and higher added-value oriented companies that develop research, in addition to the creation and application of innovations. This principle is taken into account both when negotiating with new investors and when assessing the development of existing customers;

- Klaipėda FEZ constantly educates its customers and partners on innovation topics: it organises internal seminars, training and the discussion of practical examples. The Klaipėda FEZ management company actively encourages its business community to exchange knowledge, practices and experience;

- Klaipėda FEZ management company is constantly looking for and implementing the latest and most effective regional administration systems, considering economic factors, new IT and other solutions that demonstrate an increase in operational efficiency, reduce redundant processes and contribute to the improvement of the environment, customer and employee satisfaction;

- Klaipėda FEZ actively seeks that the companies of the region cooperate with the local academic community and other partners and are able to help best realise or test their ideas, research and other innovative activities;

- In its strategy, the Klaipėda FEZ aims to increase the opportunities to establish research or competence centres, spin-offs, start-ups and other high added-value organisations in the region.

The Klaipėda FEZ management company’s solutions and projects in the field of innovation:

Green energy:

The Klaipėda FEZ management company seeks to implement and promote alternative energy and energy efficiency optimisation both in the national context and abroad. In 2020, the Klaipėda FEZ management company has become a member of the Lithuanian smart energy digital innovation hub ‘Smart Energy DIH’. The Klaipėda FEZ management company is also constantly looking for opportunities for the transformation of the region towards renewable and green energy. One of the first planned future projects is a detailed technological solution for energy resources management. Klaipėda FEZ has already implemented other pilot and permanent projects:

- Automation of the FEZ economy and utility services. In order to transform the FEZ into a modern industry and environmentally friendly zone, the Klaipėda FEZ management company is digitising the utility sector. Smart water meters installed in the FlexStart building will allow customers to get detailed information on water use and reduce excess consumption. In the near future, these meters will be installed throughout the region. It is also planned to digitise gas, electricity and waste management in the future.

- General electricity purchases. We have the opportunity to combine the electricity purchases of FEZ customers, thus giving companies greater negotiating power and lower prices.

Sustainable mobility:

Sustainable mobility is one of the long-term priorities of the Klaipėda FEZ management company. We aim to promote public and alternative transport, the cooperation of colleagues travelling to and from work and other mobility solutions that are beneficial for health and the environment.

In recent years, Klaipėda FEZ has already implemented sustainable mobility solutions such as the development of pedestrian and bicycle path infrastructure, the expansion of a short-term car rental activity zone into the Klaipėda FEZ, and successful negotiations with the city municipality on the improvement and development of public transport routes, etc.

In the near future, the Klaipėda FEZ management company is planning new innovative projects in the field of sustainable mobility.

- Traffic flow monitoring system. In the first half of 2021, it is planned to install four transport and several public transport and bicycle (anonymous) registers. This data will allow for the qualitative and real-time assessment of the current traffic situation in the Klaipėda FEZ and will help in making future decisions for the improvement of the transport sector in the region.

- Smart parking system. In the second half of 2021, the Klaipėda FEZ management company plans to equip newly installed parking lots and streets with smart parking sensors integrated into the Internet of Things network. These data will be integrated into an information system, also planned to be developed, which will be able to indicate in real time the availability parking spaces in the area to drivers, thus reducing travel times and reducing the problems caused by off-site parking.

Digitisation:

The Klaipėda FEZ management company seeks to create a favourable infrastructure for digitisation solutions. Any digitisation solution requires networks that transmit data quickly, efficiently and simultaneously to serve a large number of internet sensors and devices.

In the field of data sales infrastructure required for digitisation and industrial 4.0 solutions, the Klaipėda FEZ management company implements the following solutions:

- Pilot 5G network. At the end of 2020, two, fifth-generation mobile communications (5G) base stations were installed in the territory of Klaipėda FEZ by the telecommunications company ‘Telia’. Thus, Klaipėda FEZ became the first production and business territory in Lithuania, fully covered by a 5G connection. This technology provides incomparably faster connectivity, less latency, and the ability to service more internet-connected devices simultaneously. In 2021, the Communications Regulatory Authority of the Republic of Lithuania plans to auction official 5G frequencies, primarily in the 700 MHz band.

- Narrowband Internet of Things network. In the middle of 2021, the Klaipėda FEZ management company plans to launch a Narrowband-IoT project to install a system for connecting internet-connected items and devices, which will enable businesses and management to develop innovative solutions. The network is designed to save the energy of the transmitters and to service an extremely large number. Although the Narrowband-IoT would operate as part of a 5G network, this solution is not focused on mobile devices, but on a variety of sensors (including the aforementioned water meter project) that would not need to be recharged on a daily basis.

Other:

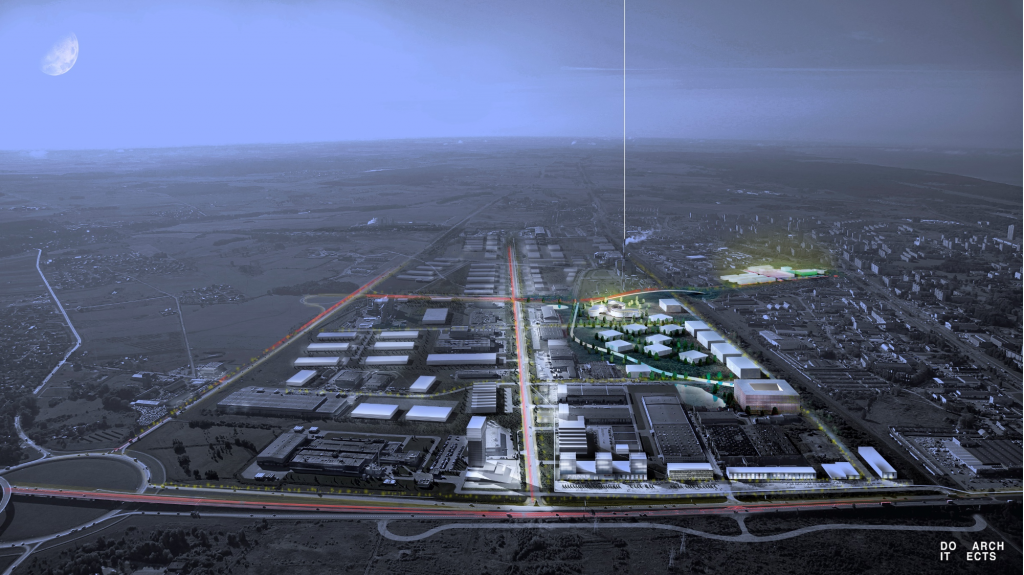

The idea of the Klaipėda FEZ Industrial Innovation Competence Centre.

Klaipėda Free Economic Zone management company wants to develop an Industrial Innovation Competence Centre (IICC) project in the FEZ region, which would help manufacturing companies to get acquainted with the latest digitisation, automation and other technologies and test them in practice. The feasibility and pace of project implementation would depend on the available funding sources.

The IICC would unite companies and organisations of various scales: ‘major’ excellence and technology partners (such as technology developers, universities or research organisations) that would have the opportunity to demonstrate their technological solutions, in addition to larger and smaller manufacturing companies that would be able to consult, experiment, plan and implement innovations in digitisation and other areas. The IICC would also be open to industrial start-ups, who would have access to both the unique technological base and the knowledge and experience of well-known manufacturing companies.

According to the Klaipėda FEZ, the IICC could have a primary focus on the sectors of smart energy, water treatment technologies, logistics and the plastics industry, and the centre itself would be open to current and future FEZ customers, in addition to other companies in the Klaipėda region, Lithuania and other Baltic countries.

The competence centre would perform various ‘hard’ and ‘soft’ functions – perform audits, consult with companies and help them plan and implement digitisation projects, provide practical training, offer training factory spaces for gaining technological knowledge and competence development. It would also promote the exchange of competencies and knowledge, help industrial start-ups, and additionally provide prototyping and demonstration opportunities.

As a building or complex, the IICC would be located in an area already designated for that purpose in the western part of the FEZ. Modern offices and other innovation spaces could be developed around the Competence Centre in the future.

—

In October 2021, Klaipeda FEZ received the main award in the category of digitisation in Investment Monitor’s Economic Zone Sustainable Recovery Strategies Awards, as well as additional mentions in the fields of Industry 4.0 and positive impact on the city. Klaipėda FEZ earned the overall award in the digitisation category thanks to its constant progress toward digitising the territory while developing the model of a sustainable, smart and green industrial zone as per the general EU vision. The FEZ is currently implementing or has completed projects in spheres such as smart car parking, traffic volume monitoring, the internet of things for manufacturing, green energy and others. The organisers also took note of the FEZ’s initiatives in the industry 4.0 context.

SOLUTIONS AND PROJECTS OF THE KLAIPĖDA FEZ COMPANIES IN THE FIELD OF INNOVATION

We are inviting you to get acquainted with the solutions of some of the Klaipėda FEZ companies in the field of research, alternative energy, sustainable mobility and digitisation. Apart from them, we have of course, many more good practices and will constantly strive to update this section.

VĖJO PROJEKTAI

Area of business: development and production of electric transport.

Green energy:

All the electricity for production needs and for the charging of customers’ buses is purchased from wind energy producers. Existing legislation and electricity trading rules allow for contracts with producers through independent electricity suppliers, and direct purchases from the producers of wind energy allow them to have stable and secure incomes and further expand their capacity.

The company uses return steam condensate from heating networks to heat its industrial and administrative premises.

Sustainable mobility:

Most of the company’s employees go to work by bicycle and are, thus, provided with facilities for storing bicycles at work and charging electric bicycles/scooters. The company is equipped with ten electric car charging stations.

In addition, the company is developing and manufacturing a product that aims to replace polluting diesel city buses with electric buses, thus encouraging employees to use public transport.

Digitisation:

The company has implemented and successfully operates the PLM (Product Lifecycle Management) Aras Innovator System; the modules of engineering programmes, ERP (Enterprise Resource Planning), raw material and goods movement, job accounting, finance and production are fully digitised. The system allows the effective planning and execution of the company’s activities by constantly monitoring various indicators and therefore making the necessary decisions so much easier.

Scientific research:

Since 2011, ‘UAB Vėjo projektai’, in close cooperation with Lithuanian and foreign university researchers, has been developing, designing and manufacturing the original and unique Lithuanian electric ‘Dancer’ city buses, in addition to the infrastructure required for their operation. The company also offers a unique package of services that satisfies public interest in providing transport. It is the first and currently the only company in Lithuania to have acquired the globally issued status of a vehicle manufacturer. The developed product is based on the results of research and experimental development, and significantly outperforms other electric city buses already being sold on the market.

The electric city bus ‘Dancer’, developed and manufactured in Klaipėda, is the only 100 % electric vehicle that has gone through all stages of technological and business cooperation, from research and experimentation, innovation, prototyping, testing, product commercialisation, full technical support, to small-scale and, later, planned mass production.

The company has been carrying out research activities continuously from the very beginning and they are its main centre of added value and competencies.

The company is also in close cooperation with Klaipėda, Kaunas University of Technology, Vilnius Gediminas Technical University in Lithuania, as well as TU Delft, Alborg and Lund universities in Europe. The company is an associate member of the CFK Valley Stade (aerbus composite cluster).

![]()

NEO GROUP

Area of business: PET, plastics industry

Green energy:

Since 2015, NEO GROUP has been using a biofuel boiler house for its energy needs, and since 2020 – a 1 MW solar power plant. The company buys electricity produced 100 % from renewable sources and constantly invests in energy efficiency projects.

Sustainable mobility:

NEO GROUP organises transportation of employees to and from the city.

Digitisation:

NEO GROUP has been implementing an automated production process from the start. An automation system for documents (invoices, etc.) is currently being implemented.

Scientific research:

NEO GROUP is actively involved in the development of the circular economy as a participant in ‘Horizon 2020’ projects, which are a part of the programme supported by the European Commission: the DEMETO programme aims to promote the collection and recycling of plastic waste, and the SYMBIOPTIMA programme aims to optimise natural resources and process costs (including energy, raw materials, water, etc.).

Since 2011, NEO GROUP has been using the method developed by the company’s research team to convert the by-products of PET production into polyols that are widely used in the construction industry.

Throughout the period 2019–2020, the company’s research team has developed a unique recycling and manufacturing technology that allows the manufacture of PET granules using 25 % of recycled material. The company started the process of patenting this invention in the EU in 2020. The company’s invention makes it possible for the NEOPET CYCLE granules to be of the same quality as the standard product. When using them, the company’s customers are not required to modify their equipment or production processes. NEO GROUP continues to conduct research to increase the share of recycled raw materials used in production.

![]()

LAVANGO ENGINEERING LT

Area of business: manufacture of food industry equipment

Green energy:

The company plans to implement a renewable energy project and eco-design initiatives and apply them to all relevant areas.

Sustainable mobility:

The company plans to install an electric car charging station for employees, and additionally encourage them to play sports and participate in joint hikes.

Digitisation:

The company is expanding the amount of web-based software it uses. A new software system (Wiseteam) has been installed for sales and project management. ‘Contour’ is used to control manufacture. Most of the company’s meetings have moved to online forms, and ‘Office 360’ has become a great tool for document sharing and video conferencing. It is also planned to create a virtual tour of the production facilities.

Scientific research:

In 2021, the company has admitted a student from the Hanze University of Applied Sciences in Groningen, the Netherlands, to conduct research for his Bachelor’s degree and prepare an analysis of ‘Lavango’s’ entry into the German market.

Also in 2021, Lavango Engineering LT started developing a smart spiral freezer together with scientists from the Kaunas University of Technology. The novelty will open doors to a more efficient food freezing process and will reduce energy consumption. The product will feature a non-invasive monitoring system that will select a freezing regime according to a particular product and its properties.

![]()

RETAL BALTIC FILMS

Area of business: food-packaging solutions

Green energy:

The company buys electricity made 100 % from renewable sources.

Sustainable mobility:

The company’s employees cooperate when travelling to and from work.

Digitisation:

In 2020, the company has been implementing a large-scale project to digitise production, storage renovation and management processes. Optimisation of the planning of production allows for more efficient productivity, and the reduction of production defects.

Some storage locations have been robotised to make optimal use of storage space.

Scientific research:

Since 2016, the company has been carrying out research and product testing projects in Klaipėda, and the company’s laboratory has obtained the certificate of one of the world’s largest beverage manufacturers. ‘RETAL Baltic Films’ research capabilities to date have successfully enabled the company to develop research, development and testing of tethered caps, thus contributing to the return of more packaging items for recycling and meeting the objectives of the Single-Use Plastics EU Directive.

In 2020, the company completed a project resulting in EUR 1 million being invested in the development of the laboratory. The upgraded laboratory will allow the company to simulate the packaging process of its customers’ beverages and food products using the company’s packaging elements, thus speeding up research and offering more sustainable packaging innovations to the market. In 2021, further investments (EUR 570,000) in laboratory equipment are planned.

In 2021, the company received EU funding under the ‘COVID-19 R&D’ measure for the project ‘Development and Use of Multilayer Film with Virucidal (Against SARS-COV-2) Properties in the Development of Face Shield Prototype Carrying out R&D Activities’. Funding amounted to EUR 522,097.84.